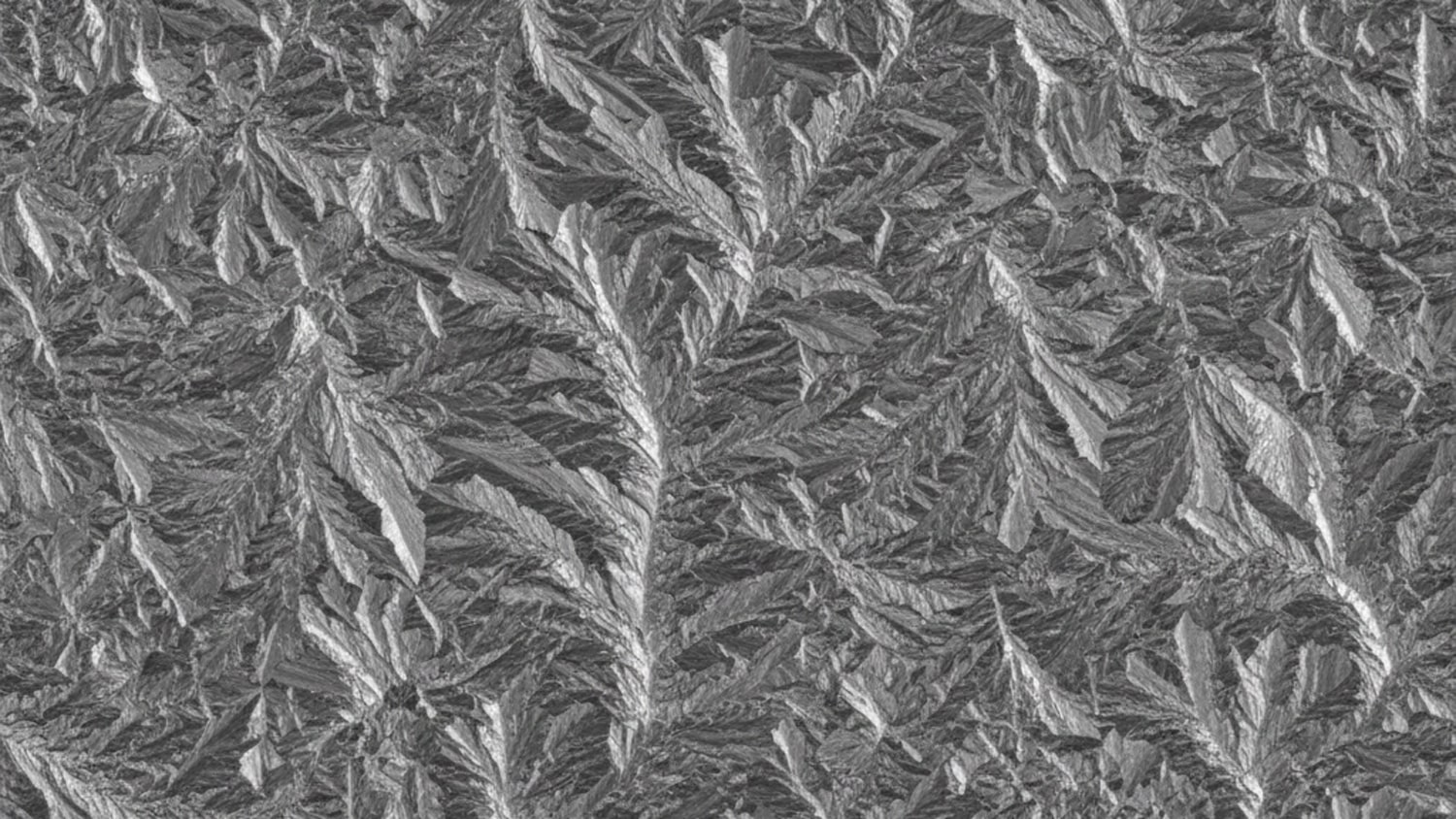

Solidification is not just about cooling down; it is a complex phase transformation where the metal’s internal structure (grain structure) is formed. This stage determines whether the part will be brittle or tough. At Avangard, we control the cooling rate precisely. By using directional solidification techniques and exothermic sleeves (feeders), we ensure the metal freezes from the furthest point towards the feeder, eliminating shrinkage cavities and internal porosity.

Solidification is where molten metal transitions into its final internal structure — defining strength, durability, and long-term performance. By controlling cooling rates, managing grain formation, and optimizing feeding systems, we guide the metal through a stable, defect-free transformation. This engineered process ensures dense microstructure, minimized shrinkage, and reliable mechanical properties for demanding industrial applications.

Each workflow below illustrates the essential steps required to transform raw concepts into fully engineered, production-ready components.

This structured process ensures precision, repeatability, and quality at every stage.

As the molten metal temperature drops below the liquidus point, tiny solid crystals called “nuclei” begin to form. These grow into tree-like structures called “dendrites.” The size of these grains matters: fast cooling creates fine grains (stronger metal), while slow cooling creates coarse grains. We optimize this rate based on the alloy type to achieve the desired mechanical properties.

Metal shrinks as it solidifies. If not managed, this leads to holes inside the part. We use “Risers” or “Feeders”—reservoirs of extra liquid metal that remain hot longer than the casting. As the part shrinks, the feeder supplies liquid metal to fill the void. This technique, known as “Directional Solidification,” is the key to producing sound, defect-free castings.

Once the solidification is complete, the casting must cool down to a safe handling temperature inside the mold to prevent warping or cracking (hot tears). After sufficient cooling, the mold is broken (Shakeout process) to reveal the rough metal casting, now ready for the finishing stages.

Induction furnaces offer superior control over temperature and chemistry. Unlike Cupola furnaces that use coke (coal) and can introduce impurities like sulfur, induction melting is cleaner, eco-friendly, and allows for precise alloying, which is essential for producing high-grade steels and ductile iron.