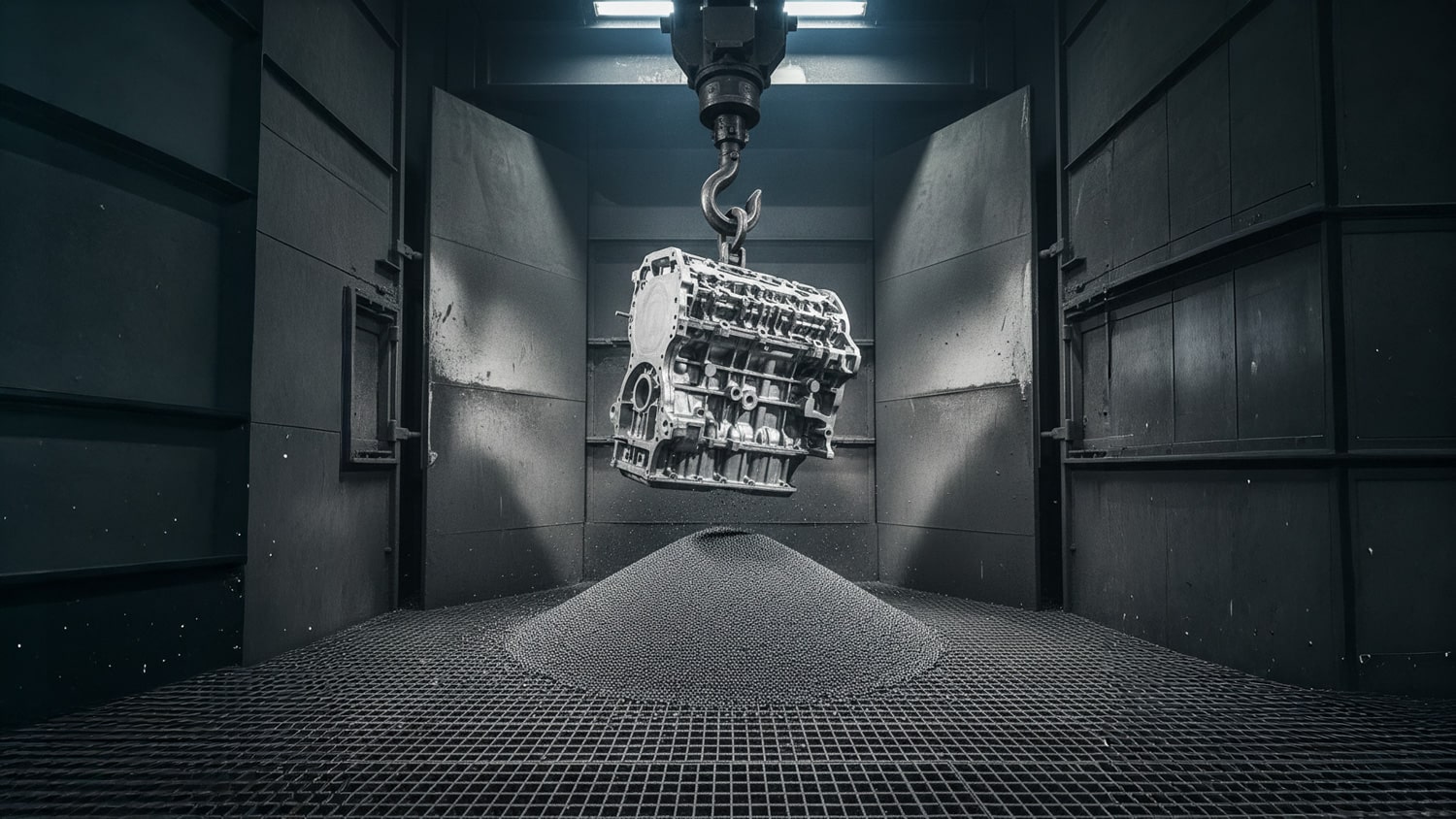

When a casting is removed from the mold, it is not yet a finished product. It is attached to gates, risers, and vents (the feeding system) and covered in burnt sand. The “Fettling” or Finishing stage is the bridge between the foundry and the machine shop. At Avangard, we use heavy-duty cutting, shot blasting, and precision grinding to remove these excess materials, cleaning the surface and bringing the part to its final net shape.

Fettling and finishing transform raw castings into clean, dimensionally accurate components ready for assembly or machining. Through controlled shot blasting, precise gate removal, and expert grinding operations, we eliminate excess material, refine the surface, and bring each part to its final engineered form—ensuring reliability, consistency, and a professional industrial finish.

Each workflow illustrates the essential stages that transform raw concepts into fully engineered, production-ready components—ensuring precision, repeatability, and quality at every step.

The first step after shakeout is to remove the burnt sand sticking to the metal. We place the castings into a Shot Blast machine, which bombards them with high-velocity steel shots (tiny steel balls). This abrasive action strips away all sand, rust, and scale, leaving the casting with a clean, uniform, matte-silver surface finish ready for inspection.

During pouring, extra metal fills the “gates” (channels) and “risers” (feeders). These must now be removed. For ductile iron or smaller parts, we may use hydraulic wedges. For large steel castings, we use Oxy-Fuel torches or Plasma cutters to slice through thick metal sections. This separation is critical to separate the product from the scrap metal that will be remelted.

After cutting, sharp edges and “pads” (where the risers were attached) remain on the part. Using swing grinders or handheld pneumatic grinders, our operators smooth out these areas, remove parting lines (flash), and ensure the casting dimensions meet the tolerance requirements. The result is a smooth, safe, and dimensionally accurate component.

Induction furnaces offer superior control over temperature and chemistry. Unlike Cupola furnaces that use coke (coal) and can introduce impurities like sulfur, induction melting is cleaner, eco-friendly, and allows for precise alloying, which is essential for producing high-grade steels and ductile iron.