Quality isn’t an accident; it’s the result of rigorous testing. At Avangard, our Laboratory is the heart of our guarantee. We don’t just “look” at the parts; we analyze their DNA. From checking the chemical composition to testing the physical strength limits, our QC process ensures that every single casting meets ISO standards and customer specifications before it leaves the factory. We employ both Destructive (DT) and Non-Destructive Testing (NDT) methods.

Our quality laboratory verifies every critical property before a component moves to production. From chemical analysis and microstructure evaluation to destructive and non-destructive testing, each examination is performed with precision to ensure full compliance with international standards. This rigorous process guarantees that every casting leaving our facility delivers consistency, reliability, and long-term performance under demanding industrial conditions.

Each workflow below illustrates the essential steps required to transform raw concepts into fully engineered, production-ready components.

This structured process ensures precision, repeatability, and quality at every stage.

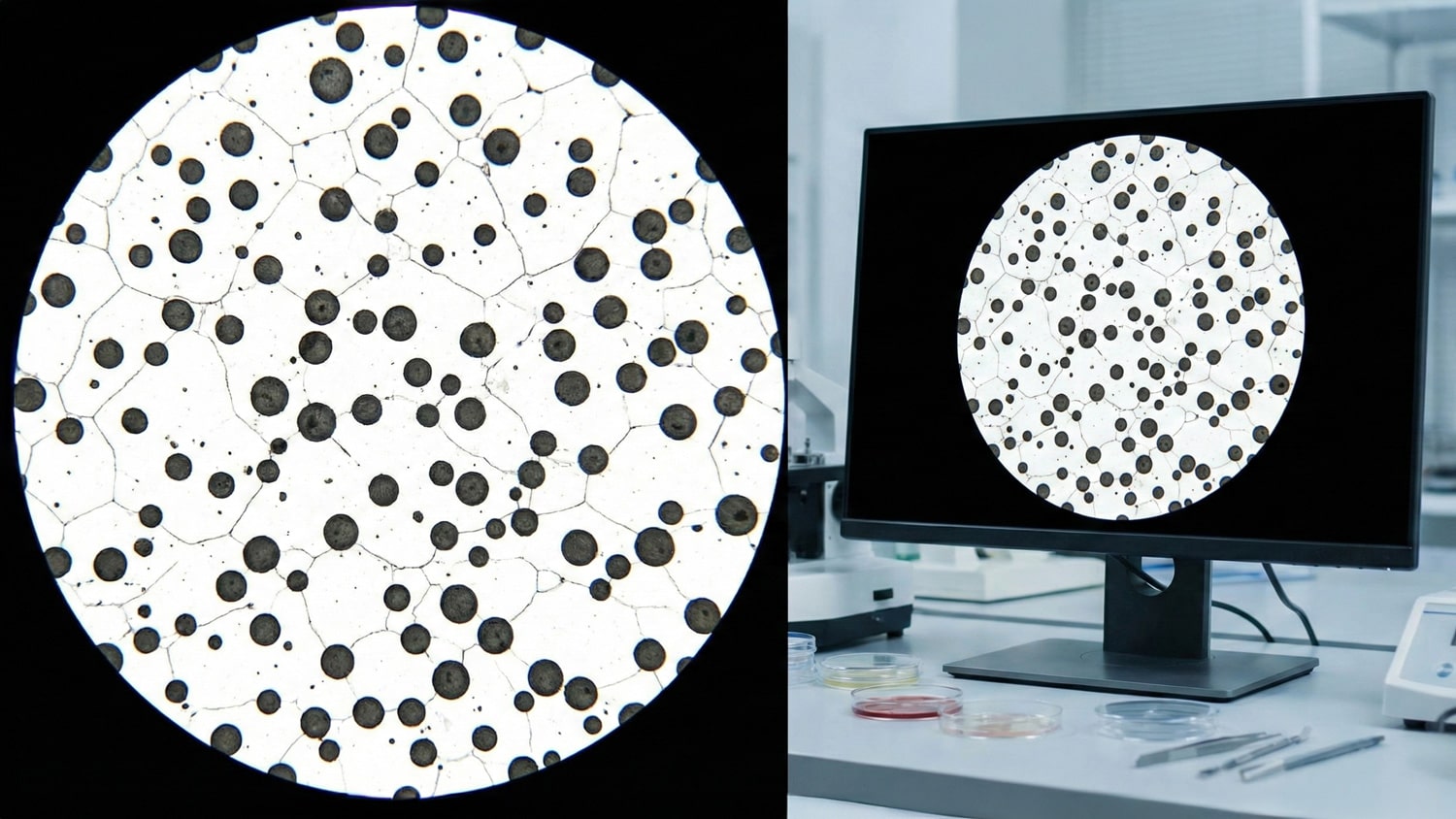

Chemistry alone isn’t enough; structure matters. Using high-powered optical microscopes, we perform “Metallography.” We polish a small sample of the casting to a mirror finish and examine its internal grain structure (e.g., graphite nodularity in Ductile Iron). This confirms that the heat treatment was successful and the metal matrix is correctly formed.

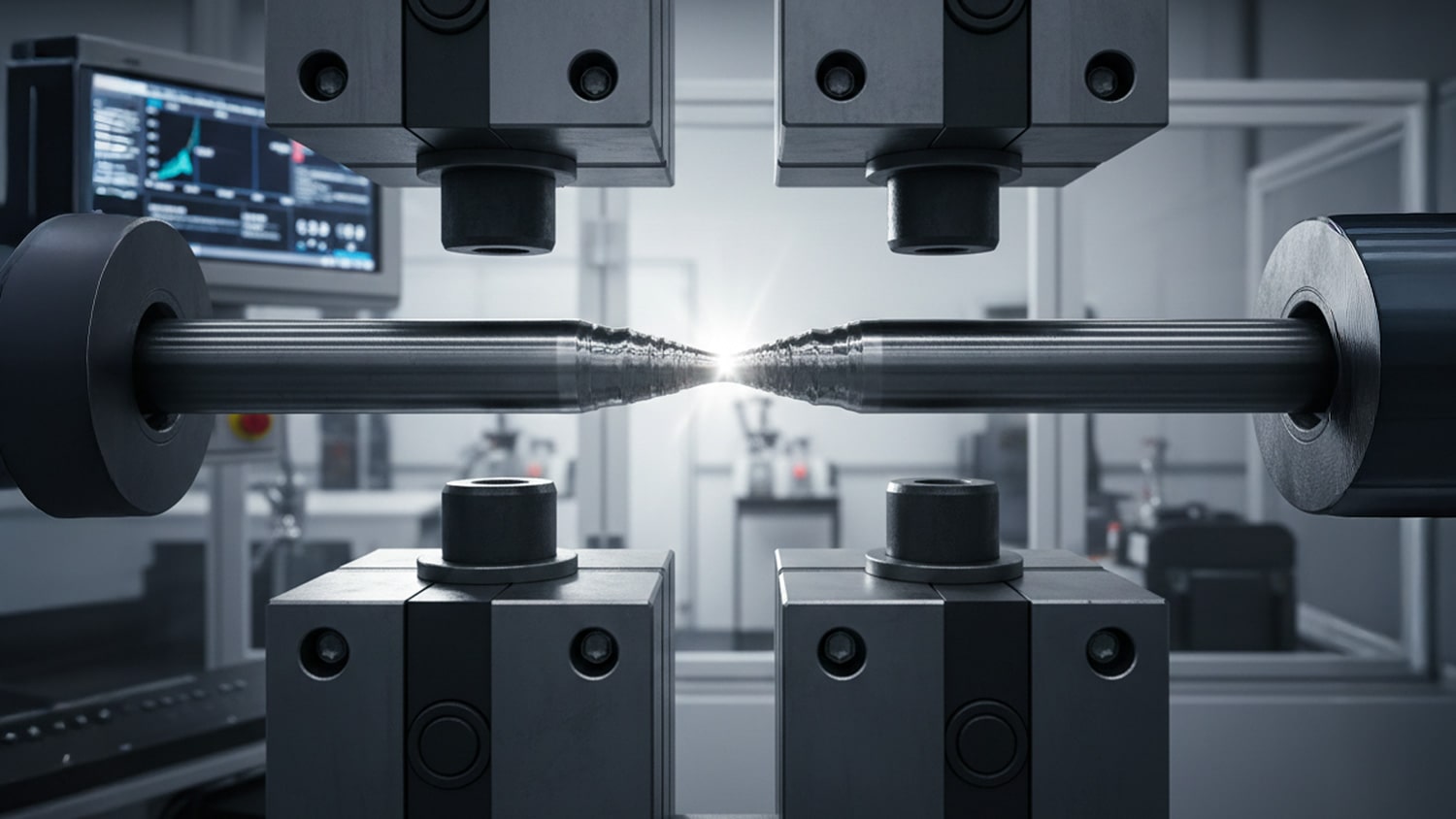

How strong is the part? We find out by breaking sample blocks. Using Universal Testing Machines, we perform **Tensile Tests** (pulling metal until it snaps) to measure yield strength. We also perform **Impact Tests** (Charpy V-Notch) to measure toughness and **Hardness Tests** (Brinell/Rockwell) to ensure wear resistance. If a batch fails these tests, it is rejected immediately.

To find hidden defects without damaging the actual product, we use NDT. This includes **Ultrasonic Testing (UT)** to detect internal cracks, **Magnetic Particle Testing (MT)** for surface cracks in ferromagnetic materials, and **Dye Penetrant (PT)** for surface pores. This ensures that the part is sound inside and out, with no invisible weaknesses.

Induction furnaces offer superior control over temperature and chemistry. Unlike Cupola furnaces that use coke (coal) and can introduce impurities like sulfur, induction melting is cleaner, eco-friendly, and allows for precise alloying, which is essential for producing high-grade steels and ductile iron.