Pattern making and design constitute the most critical phase in the casting lifecycle. The final dimensional accuracy and metallurgical integrity of a part are defined right here. Moving away from traditional manual errors, we utilize advanced CAD/CAM software and solidification simulations to eliminate risks before production. Whether it is a massive mining component or a complex industrial part, our process ensures a flawless start.

Our modern approach to pattern engineering combines digital modeling, CNC machining, and precise material selection to deliver production-ready patterns with exceptional dimensional accuracy. From early concept evaluation to final machining, every stage is engineered to minimize risk and ensure flawless results in downstream casting operations.

Each workflow below illustrates the essential steps required to transform raw concepts into fully engineered, production-ready components.

This structured process ensures precision, repeatability, and quality at every stage.

Everything starts with a concept or an existing part. If you have technical drawings, we analyze them immediately. However, if you possess a part without blueprints, our engineering team utilizes advanced 3D laser scanners and precise measuring tools to perform reverse engineering, creating a reliable digital twin of your component.

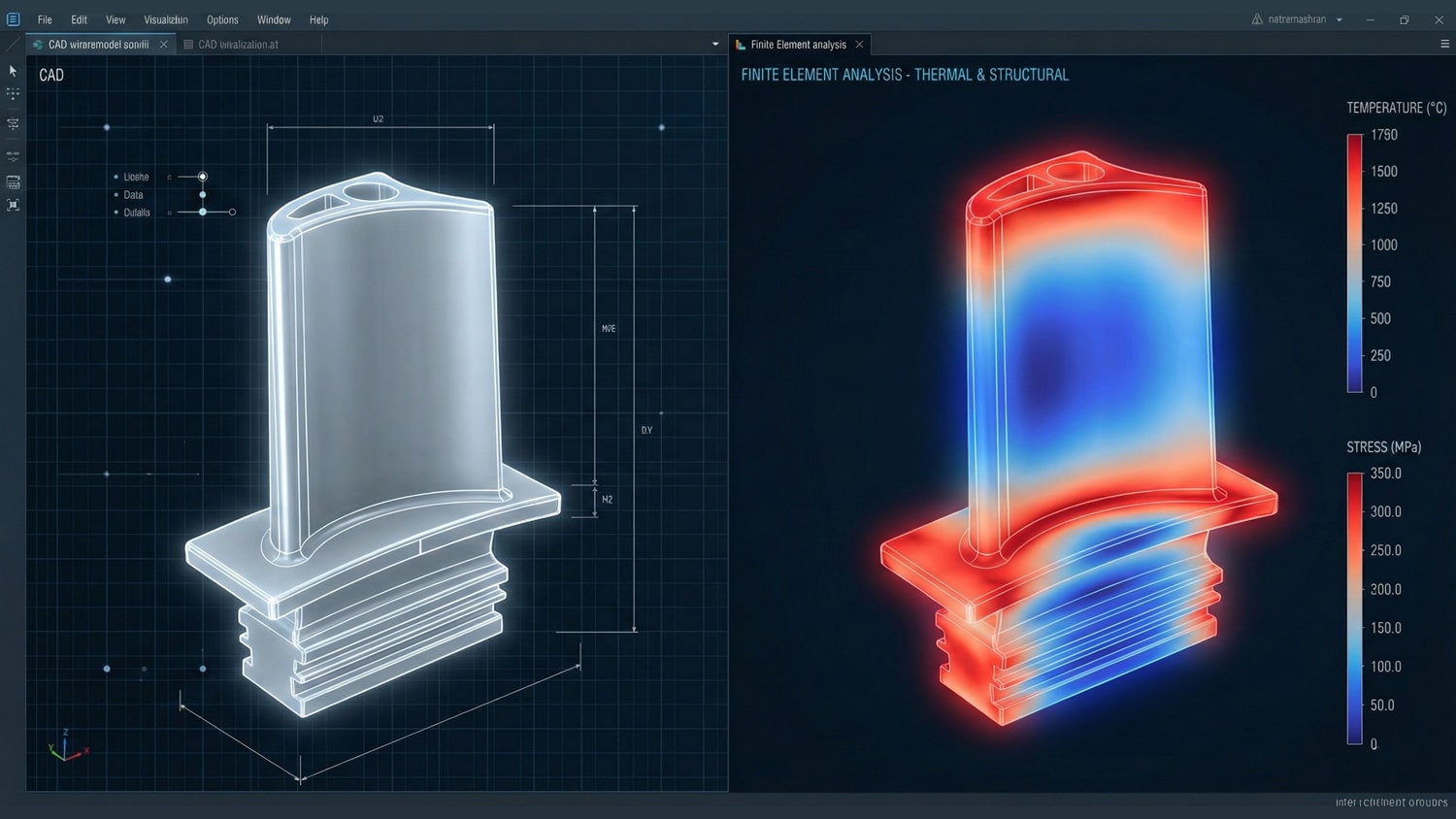

Before any material is cut or melted, the part is constructed virtually. Using software like SolidWorks or Catia, we create the 3D model. Then, using powerful simulation tools like ProCAST, we analyze the molten metal flow and cooling rates. This crucial step predicts and prevents potential defects such as porosity or shrinkage cavities before actual production.

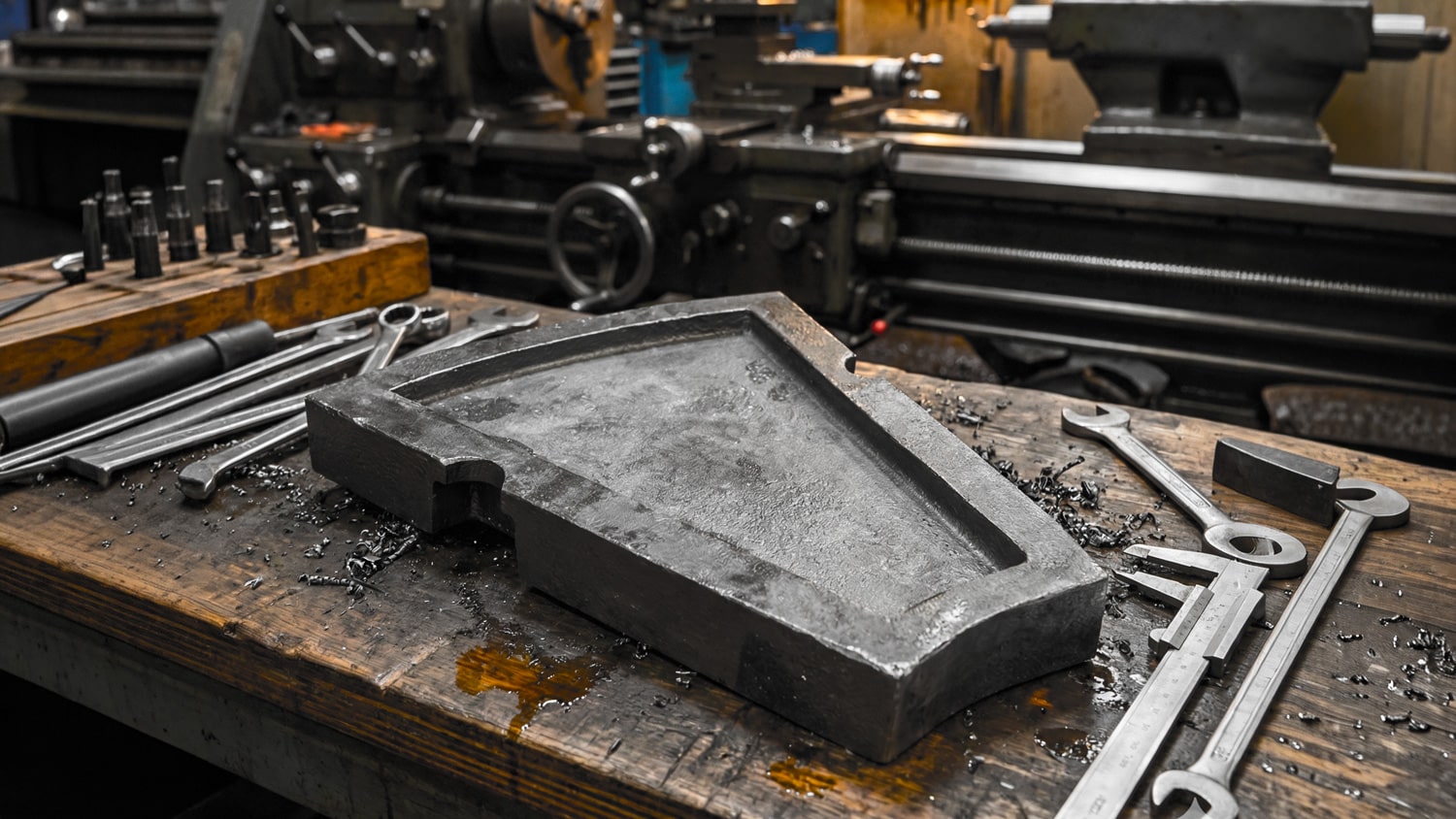

Once the design is approved, the data is sent to our high-precision CNC machines. The pattern material is selected based on production volume: “Styrofoam (Lost Foam)” for large, single-run complex parts, “Wood” for medium batches, and “Aluminum/Metal” for mass production. Our CNC accuracy ensures the pattern matches the engineering specs down to the micron.

This FAQ section summarizes important technical points about our casting and pattern-engineering processes. It helps you understand essential considerations, performance factors, and practical details before moving forward with design, manufacturing, or material selection.