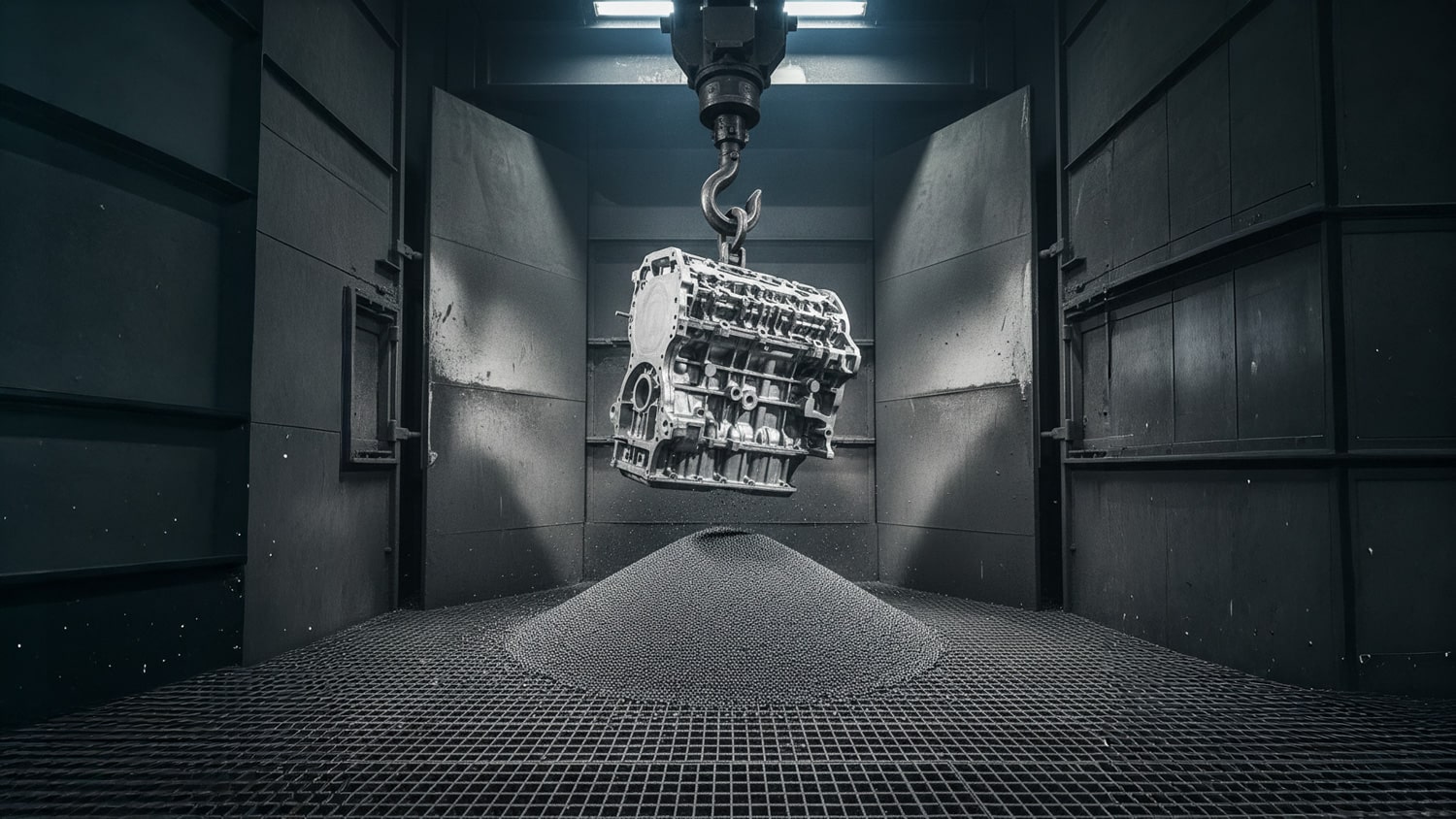

If the pattern is the positive, the mold is the negative that defines your product’s reality. Molding and Assembly involve preparing the refractory material (usually silica sand with binders), compacting it around the pattern, and precisely placing cores to create internal hollows. At Avangard, we utilize advanced molding methods like CO2 (Sodium Silicate) and Furane Resin (No-Bake) to ensure high surface finish, dimensional stability, and gas permeability, minimizing defects like blowholes or metal penetration.

Industrial molding transforms prepared sand, binders, and precision-made cores into a fully assembled mold ready for metal pouring. Through controlled compaction, accurate pattern placement, and final mold sealing, this stage ensures dimensional stability, clean cavity formation, and reliable performance during casting—laying the foundation for defect-free, high-quality components.

Each workflow illustrates the essential stages that transform raw concepts into fully engineered, production-ready components—ensuring precision, repeatability, and quality at every step.

The process begins by mixing high-quality silica sand with specific binders. Depending on the part’s requirement, we use the CO2 process (for quick hardening) or Resin Bonded Sand (for high strength and excellent surface finish). The mixture is rammed around the pattern in the flask to capture every intricate detail of the design before it hardens.

For parts requiring internal cavities (like pump casings or valves), simple molds aren’t enough. We manufacture “Cores”—solid sand shapes that block the metal from filling certain areas. These cores are baked for strength and carefully placed inside the mold cavity. This step requires extreme precision, as any shift in the core will result in uneven wall thickness.

Each workflow below illustrates the essential steps required to transform raw concepts into fully engineered, production-ready components.

This structured process ensures precision, repeatability, and quality at every stage.

Induction furnaces offer superior control over temperature and chemistry. Unlike Cupola furnaces that use coke (coal) and can introduce impurities like sulfur, induction melting is cleaner, eco-friendly, and allows for precise alloying, which is essential for producing high-grade steels and ductile iron.