Samen Zob produces high-performance cast components engineered to meet the rigorous mechanical, thermal, and operational demands of heavy industries. Every product is manufactured through controlled melting processes, precise molding methods, advanced heat-treatment cycles, and strict quality verification. These engineered components deliver long-term durability, dimensional stability, wear resistance, and reliable performance in mining operations, aggregate production, crushing systems, oil & gas applications, and other harsh industrial environments. Each part undergoes full inspection and validation to ensure consistent, dependable operation throughout its service life.

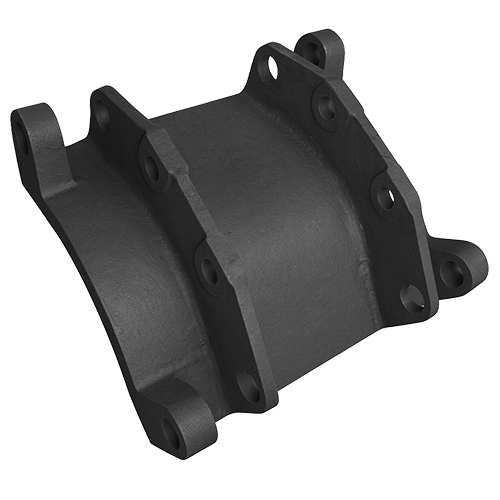

HS10 Palani (Impact Block)

The HS10 Palani, a main component of the Böhringer HS10 crusher, is made of manganese steel or impact-resistant alloy. Weighing 820 kg, it absorbs crushing impacts, enhances machine stability & reduces vibration. Its robust design ensures long service life & reliable performance in demanding mining & aggregate operations.

These related components are engineered to complement the performance, material characteristics, and operational demands of the primary product. Each item is manufactured using high-quality casting processes and precise dimensional control to ensure compatibility, durability, and long service life across industrial applications.